Educational

Information

Efflorescence

The term efflorescence is used to describe salts and other water-soluble materials coming tothe surface of concrete. Efflorescence is normally white mineral deposits that can show up on the surface of the concrete. This can be caused by a number of things, some of which consist of rain, dew, water added to fresh concrete for troweling and low temperatures. This excess in moisture pushes through the pours of the concrete and can transport calcium hydroxide,sodium, and/or potassium to the surface. While these minerals can be common in concrete, exposure to large amounts or consistent amounts of moisture can cause them to show in the form of efflorescence.

Efflorescence can be treated through specialty products, and steps can be taken to help prevent its exposure. Services like moisture treatments, vapor barriers, and sealing will all help combat efflorescence. While efflorescence is treatable, it should be noted that there is no way to fully prevent or remove efflorescence from a concrete slab, as the porous nature of concrete will be prone to moisture.

Should efflorescence arise in your concrete, we will work with you to find the best treatment and ensure that you have a Stellar floor.

Aggregate Inconsistencies

When regular concrete or modified overlay toppings (polishable wear toppings) are poured, the aggregate disperses organically and in an uncontrolled manner. Many people have expectation disconnects in this detail around these floors. But a practical reality is that these floors are poured in a way that cannot be controlled in a factory finish outcome or standard. And should be enjoyed and appreciated from an organic and random standpoint.

The way these floors pour, are placed and worked during this process, and also the way the aggregate sits at varying heights through the slab or the topping during settling and drying is not something that can be perfectly controlled. So when our machines begin to grind open the top of the floor surface it can only reveal what is in existence.

Note: Customer expectation versus achievable reality are often two different destinations, so make sure you have a practical expectation. These floors are never perfect, they will always have natural blemishes, inclusions and areas of aggregate inconsistency. Stellar will never promise aggregate consistency, however we do promise to do our very best to deliver the most consistent aggregate that the slab makes available. In some floors grinding deeper to attempt more consistency will only result in larger aggregate disparity to smaller aggregate, which in many cases can be less appealing. We will do everything in our power to give an even aggregate exposure; it should just be kept in mind that the aggregate is already in the cross section of the slab will ultimately dictate the finish. This detail is out of Stellar control even if we pour the topping as it is an organic placement and not something that can be controlled. Commissioning one of these floors must be done with an expectation to accept whatever the floor reveals in aggregate, color and texture once the floor surface is cut open in the process.

Uneven Concrete

Uneven or sloping concrete floors can be caused by a number of things, some of which include foundation issues and the floor not being properly leveled when it was originally poured. While not impossible to fix, this can be a daunting issue to fix. Some solutions include leveling the floor by grinding or scarifying, as well as pouring a self-leveling product over top of the existing concrete floor.

Differing Hardness

The hardness of concrete is based off of the mineral composition in the concrete itself. Hardness of concrete is judged on a scale of 1-10 called the Mohs scale of mineral hardness developed by a German geologist, Friedrich Mohs in 1812. The hardness of the concrete helps to determine how much of the surface needs to be taken off in order to achieve the desired finish. It can also be a deciding factor on if specialty tooling is needed to prevent scratching or scarring in the concrete floor. While most concrete hardens at an average level, testing the concrete hardness can help determine time frames and tolls needed to get the job done right.

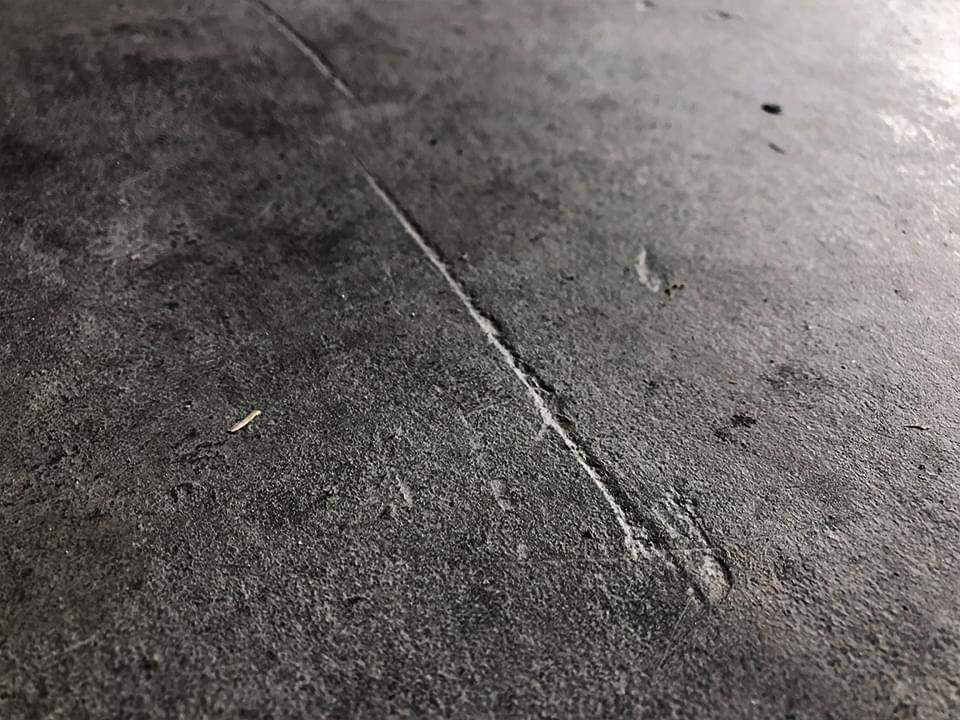

Hairline & Micro-fracture Cracks

There is a saying in the concrete industry. ‘Theres two types of concrete slabs, those that have cracks, and then, those that are about to have cracks’. Often cracks can distress customers when seen. However they are a reasonable expectation on these floors, not ideal but a common occurrence.

The reasons for cracks being present can be sourced from a

few different factors. Here’s a few of the main reasons;

shrinkage in the slab, external movement of the building

which can be triggered by earthquakes or heavy traffic like

heavy trucks creating vibrations in the building, and

structural flexing or movement.

In polished concrete these can be chased out with a diamond blade and filled with a polishable crack patch system specific to these floors. Note that the color of these products is usually darker than the main floor due to the ingredients in the product.

This will resolve the issue most of the time, however in the instance that there is a structural flex in the building, the newly patched crack may re-crack to realize the flex structurally being expressed in the building. This is not a fault of the floor, and Stellar is not responsible for this type of situation. However in this instance a flexible polyurea may be recommended, please ask your Stellar rep if this is the case.

To minimize cracks Stellar recommended cutting expansion joints into the floor in a grid pattern, and filling with a flexible polyurea to absorb much of any movement damage, however this is not full-proof and never should be seen as a one hundred percent guarantee, we highly recommend including polyurea joints in your floor planning for these reasons.

As much as we would like to say otherwise, Hairline and Micro-fractures are a part of this industry and floor expectation. And equally a crack does not indicate a ruined floor. If you have any concerns please call our office.